Opportunities will often come right up to your face and scream, I’m here, yet many people for whatever reasons, will miss out on some of the best memorable events. My Dad gave me that opportunity and I jumped on it.

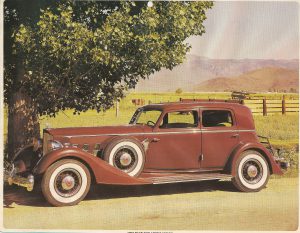

When I was fourteen years old, my Dad gave me the same proposal that he had given my two older brothers; spend the time restoring the 1934 Packard which had been sitting in the garage for some twenty years and it would be mine for $1. Dad agreed to invest all the money it would take to restore it. It was my job to invest the time. It was 1962 when I started dismantling the car in the garage.

Now, 1962 was the beginning of the British Invasion. At the time I was working, underage, at two jobs. I worked as a bowling machine mechanic, which meant being behind the machines, ready to spring into action when a bowling ball or pin became lodged and needed a little push. For that service, I got to hang out with the real mechanic and learn about machinery. At the same time, I worked the evening shift pumping gas (yes, in those days, an attendant serviced a car with gas, check the oil and washer fluid, clean the windshield, while smiling the whole time) and repairing flat tires at a Shell station next door to the bowling alley. That job, my Dad didn’t find out about until I had to call him for help. Point being, that I was busy, even at fourteen. I needed money to impress the girls, but as usual in my life, I was running out of time to do all the things I wanted to. Every available hour I spent in restoring that car taught me a lifetime of experience.

- When dismantling something, keep the parts separate and label everything you can, because memory, alone, will not work in reassembly. The four bolts that held the front bumper on were all machined individually, which meant the same looking bolt would only thread in one spot.

- Patience is vital. Letting bolt-release sit for days, returning each day to only apply more breaker juice. Shearing off the head of a bolt that is threaded into an engine head block, made of solid aluminum, is not an easy, inexpensive repair job. Thanks, Dad, for loving me…oh, and yes, also for the time I ignored the oil indicator light on the 1955 Chrysler Imperial and the engine seized at the side of the road, and you paid for the towing and the new engine as long as I put it in. And, oh yeah, my first car accident when I didn’t know what you meant by “pump the brakes on wet pavement”.

- Some people are as thick as a brick. Dad had the Chrysler dealership in Akron complete the repainting of the exterior. The guy that started stripping the old paint used a lye-based paint remover. He mishandled the material twice, putting him in the hospital, twice, with third-degree burns from the paint remover. The next guy took a sander to it and left marks that took hours to remove. These were their best specialist painters. They finished applying 16 coats of undercoat, hand sanded between each coat, followed by 12 coats of lacquer that made the most incredibly deep shine. Come to think of it, I think Dad paid $800 and that was overpayment due to the hours the two guys racked up.

- When something is right, you will know. The frosty spring Saturday morning that Dad and I drove to where the mechanics were prepared to start the engine for the first time in over 20 years. Two old guys (about three days younger than dirt) had laid on their backs under the Packard, grinding the crankshaft, by hand, because in that engine, the crankshaft could not be removed for servicing. It was a Norman Rockwell illustration right out of Saturday Evening Post or Esquire Magazine, this old wooden garage, tucked back under some trees, in what had been the repair shop area of Akron some fifty years prior. It was a frosty, yet somehow foggy spring morning. My Dad insisted on stopping on the way into town at a small store to purchase two lead pencils. He did not explain until we got to the garage their purpose. Imagine four old guys and my Dad, all proudly looking at this beautifully restored gem from a bygone era, and they gave me the privilege of starting it up. It was then that Dad stood the pencils upright, on the top of the radiator to balance vicariously while I, first, turn the key, and then push the start button on the dash. I remember so vividly pushing the button and not hearing any engine noise. I was watching Dad, who was watching the pencils – they did not move at all, indicating the engine had been tuned perfectly. I got out and could hear the hum of that 12 cylinder engine as it just purred into life resurrected. Dad stood there with the biggest shit eaten grin as he just stared at that engine, along with the mechanics as they all pointed and smiled. It was a fine day.

- I think it was the following Saturday that Dad and I went to the auto registry office in Akron and he signed over the ownership to me for the mandatory $1 required as the minimum sale amount for a vehicle. I was sixteen and it had taken me two years to complete the total restoration of a 1934 Packard, Twin Six. I had completely dismantled it and put it back together and it worked!

- I can remember many a time when Pop was not home, John and our friends would push the Packard out of the garage and stand on the running boards, pretending that we were Al Capone gangsters. We would take turns pretending we were driving. What childhood fun!

- I kept that heirloom until a guy walked up my driveway in Columbus, Ohio and offered me enough money to start my trek to Canada that summer of 1973 – but that’s another story, kids.